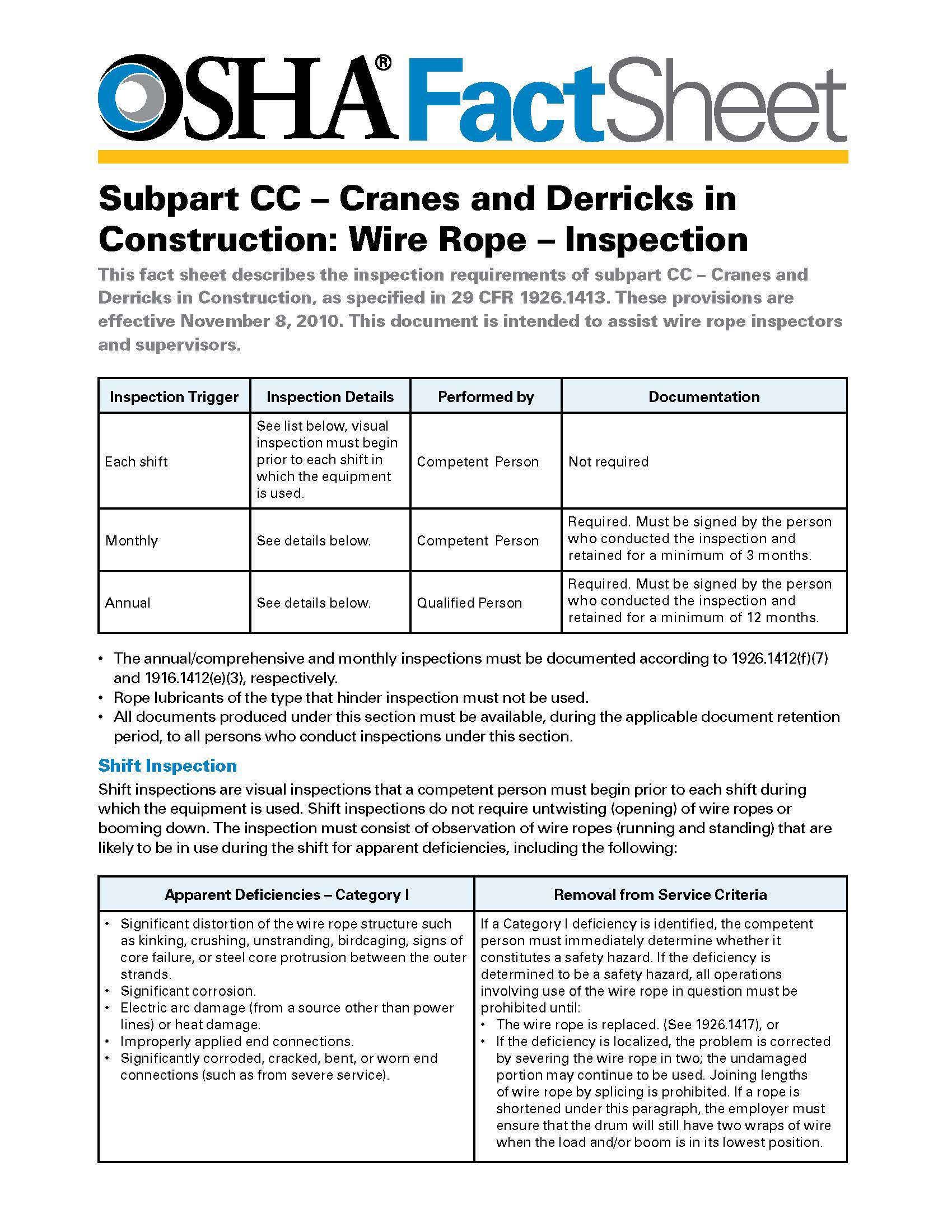

Osha Wire Rope Sling Inspection Checklist At Norma Shanks Blog Strength, ability to bend without distortion,. this checklist covers regulations issued by osha under the general industry. the types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope. Scan and learn more about wire rope sling inspection criteria.

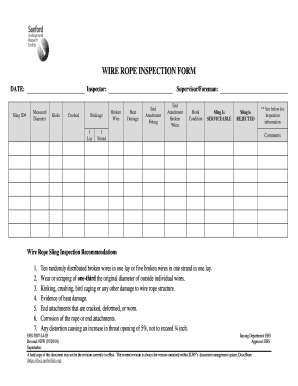

Wire Rope Sling Inspection Check List Pdf The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a) (2) of this section. Without affixed and legible identification markings. inspections each day before being used, the sling and all fastenings and attachments shall be inspected for damage or d. fects by a competent person designated by the employer. additional inspections shall be perf. rmed during sling use where service conditions warrant. damaged or def. ic. The document provides a checklist for inspecting wire rope slings with criteria for rejecting slings due to defects like kinking, crushing, broken wires, damage to fittings, rust, wear, and knots. Use this osha aligned sling self inspection checklist to assess web, chain, wire rope, and mesh slings. verify load ratings, condition, and temperatures.

Osha Sling Inspection Checklist At Kaitlyn Nuyts Blog The document provides a checklist for inspecting wire rope slings with criteria for rejecting slings due to defects like kinking, crushing, broken wires, damage to fittings, rust, wear, and knots. Use this osha aligned sling self inspection checklist to assess web, chain, wire rope, and mesh slings. verify load ratings, condition, and temperatures. Begin by visually inspecting the sling before use for any obvious signs of damage, such as cuts, kinks, crushing, knots, bird caging, or other deformities that could weaken the rope and make it more prone to breaking (see handout for some examples). Find the most worn or damaged section of the sling and carefully check it against removal criteria. label or identify all slings you’ve inspected. keep records of all inspections, including dates and conditions of slings. immediately destroy all slings you’ve rejected. Make periodic inspections of wire rope slings at intervals no greater than 12 months. This checklist is used to inspect wire rope slings used for lifting. it contains 17 checkpoints to examine the sling for defects like cuts, twisting, damage, proper storage, and legible identification markings.

Wire Rope Inspection Checklist Pdf Complete With Ease Airslate Signnow Begin by visually inspecting the sling before use for any obvious signs of damage, such as cuts, kinks, crushing, knots, bird caging, or other deformities that could weaken the rope and make it more prone to breaking (see handout for some examples). Find the most worn or damaged section of the sling and carefully check it against removal criteria. label or identify all slings you’ve inspected. keep records of all inspections, including dates and conditions of slings. immediately destroy all slings you’ve rejected. Make periodic inspections of wire rope slings at intervals no greater than 12 months. This checklist is used to inspect wire rope slings used for lifting. it contains 17 checkpoints to examine the sling for defects like cuts, twisting, damage, proper storage, and legible identification markings.

Br Lifting Sling Inspection Criteria R2 Pdf Rope Knot Make periodic inspections of wire rope slings at intervals no greater than 12 months. This checklist is used to inspect wire rope slings used for lifting. it contains 17 checkpoints to examine the sling for defects like cuts, twisting, damage, proper storage, and legible identification markings.

Osha Wire Rope Sling Inspection Checklist At Norma Shanks Blog