Lift All Wire Rope Sling How To Inspect For Damage Youtube Lift all instructional video on inspecting wire rope slings. i’m jim with lift all, and in this video we are going to explain how to properly inspect your wire rope slings. Are your wire rope slings in compliance with asme b30.9 standards? learn how to inspect wire rope slings, how often to inspect, removal criteria, and.

Lift All Wire Rope Sling Inspection Youtube To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. if necessary, remove dirt and grime so wires and components are visible. look for any of the conditions listed in the removal from service criteria. Lift all instructional video on inspecting wire rope slings. contact us for your safe lifting and load securement needs at lift all or 800 909 1964. Clean off all dirt and grease with a wire brush or rags to reveal wires and fittings. mild detergents may be used to assist in the cleaning of the product. examine the entire length of the sling thoroughly, especially the parts showing the most wear. Use this lift sling and wire rope inspection checklist to check wear, broken stitches, corrosion, distortion, and tag condition for safe lifting operations.

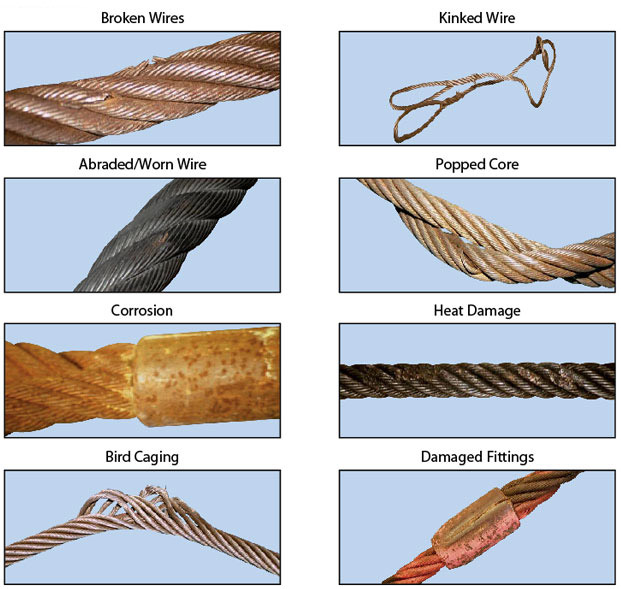

How To Inspect A Wire Rope Lifting Sling To Osha And Asme Standards L Clean off all dirt and grease with a wire brush or rags to reveal wires and fittings. mild detergents may be used to assist in the cleaning of the product. examine the entire length of the sling thoroughly, especially the parts showing the most wear. Use this lift sling and wire rope inspection checklist to check wear, broken stitches, corrosion, distortion, and tag condition for safe lifting operations. The document provides a checklist for inspecting wire rope slings with criteria for rejecting slings due to defects like kinking, crushing, broken wires, damage to fittings, rust, wear, and knots. Scan and learn more about wire rope sling inspection criteria. Best practice is to inspect the wire rope sling upon receiving it from the manufacturer. double check the sling tag to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements. Clean off all dirt and grease with a wire brush or rags to reveal wires and fittings. examine the entire length of the sling thoroughly, especially the parts showing the most wear. pay special attention to fittings and end attachments and areas of the sling next to these fittings.

Wire Rope Sling Inspection Criteria Lift It Manufacturing The document provides a checklist for inspecting wire rope slings with criteria for rejecting slings due to defects like kinking, crushing, broken wires, damage to fittings, rust, wear, and knots. Scan and learn more about wire rope sling inspection criteria. Best practice is to inspect the wire rope sling upon receiving it from the manufacturer. double check the sling tag to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements. Clean off all dirt and grease with a wire brush or rags to reveal wires and fittings. examine the entire length of the sling thoroughly, especially the parts showing the most wear. pay special attention to fittings and end attachments and areas of the sling next to these fittings.

Br Lifting Sling Inspection Criteria R2 Pdf Rope Knot Best practice is to inspect the wire rope sling upon receiving it from the manufacturer. double check the sling tag to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements. Clean off all dirt and grease with a wire brush or rags to reveal wires and fittings. examine the entire length of the sling thoroughly, especially the parts showing the most wear. pay special attention to fittings and end attachments and areas of the sling next to these fittings.