How To Inspect A Wire Rope Lifting Sling To Osha And Asme Standards L The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next inspection. note: reference asme b30.9 slings (current revision) and osha 1910.184 for detailed information regarding sling inspection requirements. Learn how to inspect a wire rope lifting sling to osha and asme standards in the first lesson of sling inspection 101. *** more.

How To Inspect A Wire Rope Lifting Sling To Osha And Asme Standards Are your wire rope slings in compliance with asme b30.9 standards? learn how to inspect wire rope slings, how often to inspect, removal criteria, and. Clean off all dirt and grease with a wire brush or rags to reveal wires and fittings. examine the entire length of the sling thoroughly, especially the parts showing the most wear. pay special attention to fittings and end attachments and areas of the sling next to these fittings. Make periodic inspections of wire rope slings at intervals no greater than 12 months. Detailed compliance guide for osha 1910.184 standards. learn the full lifecycle requirements for safe industrial sling operation and mandated removal.

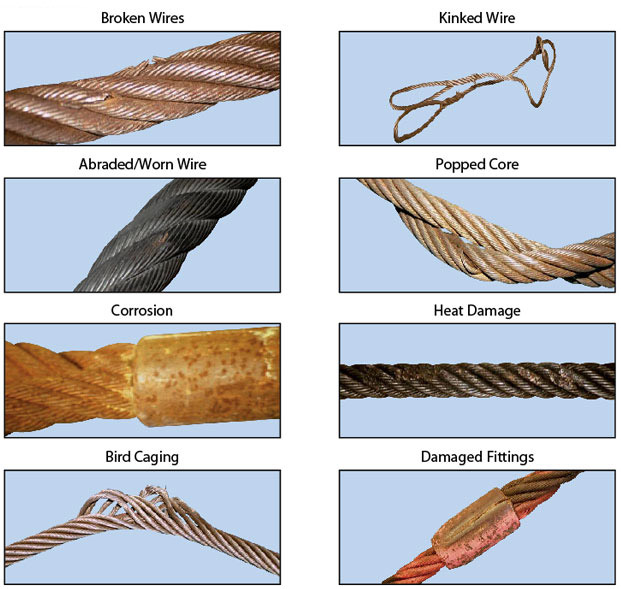

How To Inspect Wire Rope Slings According To Asme B30 9 Standards Make periodic inspections of wire rope slings at intervals no greater than 12 months. Detailed compliance guide for osha 1910.184 standards. learn the full lifecycle requirements for safe industrial sling operation and mandated removal. Learn how to inspect, maintain, & store wire rope slings. get practical tips on sling damage, ansi standards, and proper storage. Konecranes offers osha compliant sling inspections to ensure lifting equipment meets strict safety standards and maintains structural integrity. Proper inspection of your wire rope slings for damage or irregularities, prior to each use, is the best way to help keep everybody on the job site safe. learn how to inspect a wire rope lifting sling to osha and asme standards in the first lesson of sling inspection 101. Visual inspection: a visual inspection should be performed whenever a wire rope sling is used. this inspection should look for any signs of damage, such as broken wires, kinks, or corrosion. functional test: a functional test should be performed every 12 months.

Osha Wire Rope Sling Inspection Checklist At Norma Shanks Blog Learn how to inspect, maintain, & store wire rope slings. get practical tips on sling damage, ansi standards, and proper storage. Konecranes offers osha compliant sling inspections to ensure lifting equipment meets strict safety standards and maintains structural integrity. Proper inspection of your wire rope slings for damage or irregularities, prior to each use, is the best way to help keep everybody on the job site safe. learn how to inspect a wire rope lifting sling to osha and asme standards in the first lesson of sling inspection 101. Visual inspection: a visual inspection should be performed whenever a wire rope sling is used. this inspection should look for any signs of damage, such as broken wires, kinks, or corrosion. functional test: a functional test should be performed every 12 months.

How To Inspect Wire Rope Slings According To Asme Standards 50 Off Proper inspection of your wire rope slings for damage or irregularities, prior to each use, is the best way to help keep everybody on the job site safe. learn how to inspect a wire rope lifting sling to osha and asme standards in the first lesson of sling inspection 101. Visual inspection: a visual inspection should be performed whenever a wire rope sling is used. this inspection should look for any signs of damage, such as broken wires, kinks, or corrosion. functional test: a functional test should be performed every 12 months.

How To Inspect Wire Rope Slings According To Asme Standards 50 Off