Soldering Brazing And Welding Pdf Soldering Welding

Welding Brazing And Soldering Pdf Pdf Soldering Solder Apart from the use of rivets, screws, etc., metal is commonly joined by soldering, brazing, or welding, three groups of processes that have one thing in com mon— the use of heat to fuse either the metals them selves or an alloy which is interposed to consolidate the joint. The soldering bolt b was made of steel because it kept the correct shape point much longer than cast iron or copper, although the latter metal is better for transmitting the heat.

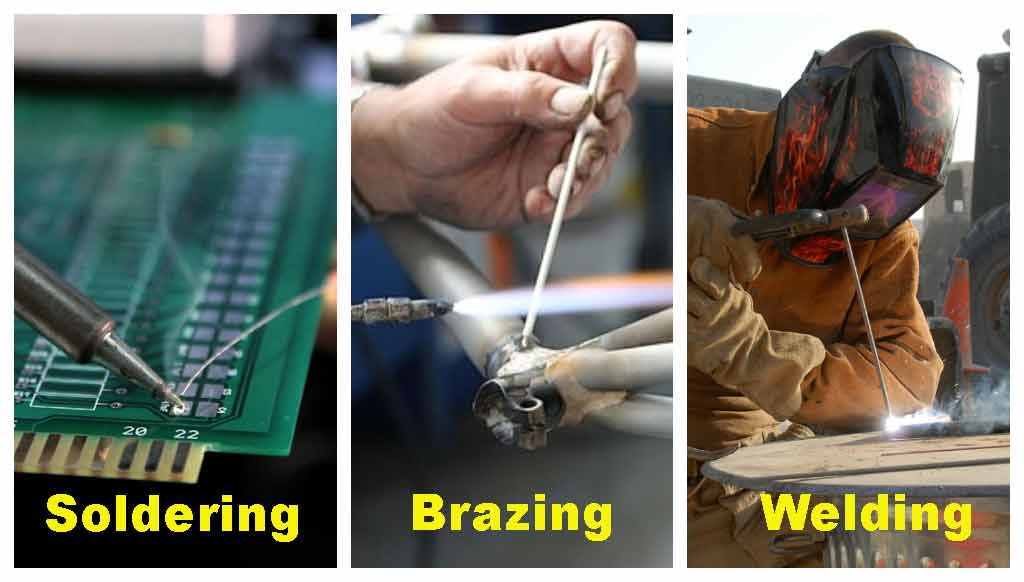

Welding Vs Soldering Vs Brazing Difference Welding, brazing & soldering.pdf free download as pdf file (.pdf), text file (.txt) or read online for free. the document discusses soldering and brazing processes. Welding and joining processes are es sential for the development of virtually every manufactarcd pmduct. however, these proc esses often appear to consume greater fractions of the product cost and to create more of the production difficulties than might be expected. What's the difference between soldering, brazing, and welding? soldering, brazing, and welding are all methods of joining two or more pieces of metal and selected other materials. they are also methods used to fill gaps in metal parts. The joint forms itself by the nature of the flow, wetting, and subsequent crystallization process, even when the heat and the braze or solder are not directed precisely to the places to be joined.

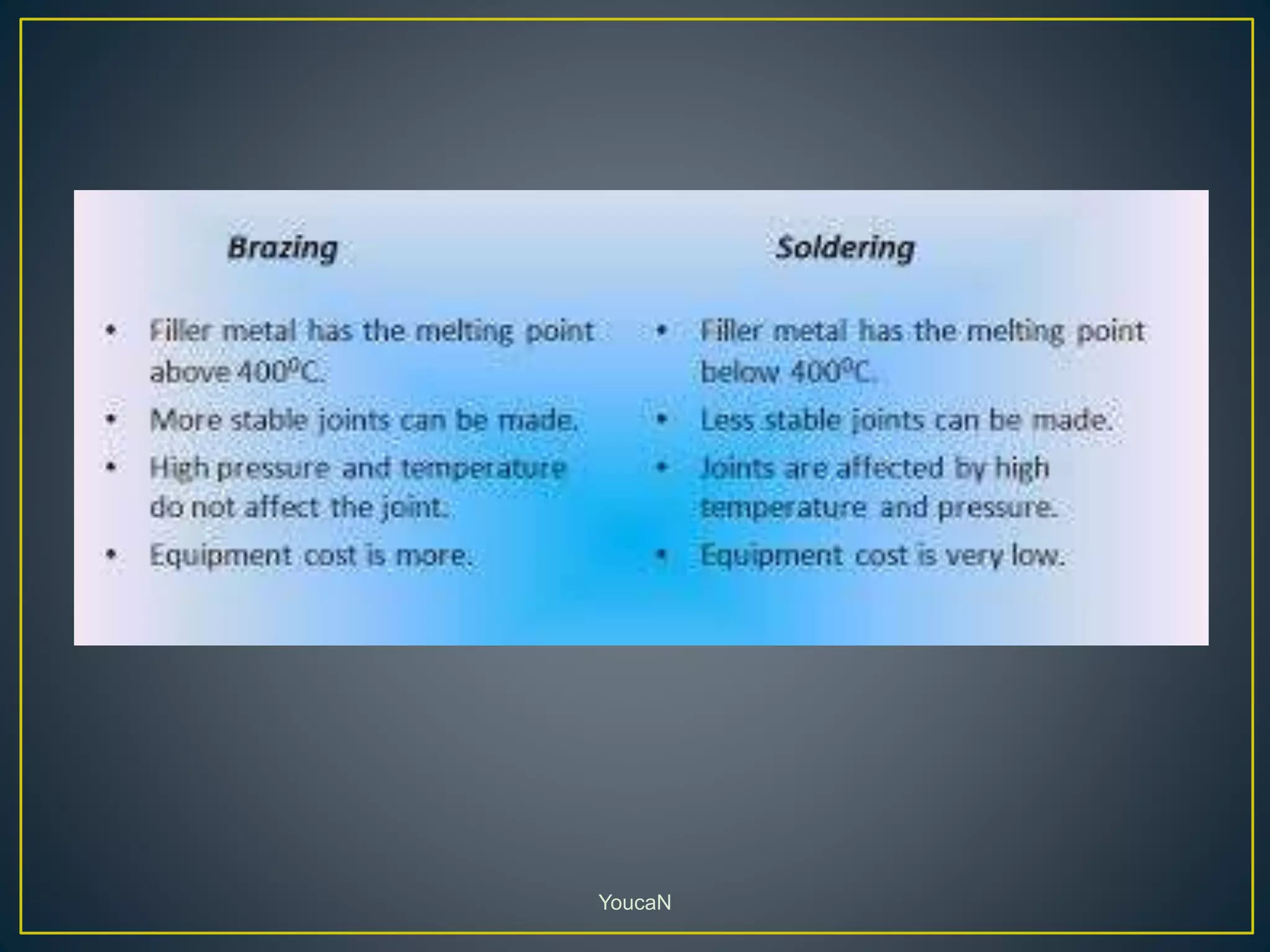

Soldering Brazing And Welding Edited By Bernard E Jones 1916 What's the difference between soldering, brazing, and welding? soldering, brazing, and welding are all methods of joining two or more pieces of metal and selected other materials. they are also methods used to fill gaps in metal parts. The joint forms itself by the nature of the flow, wetting, and subsequent crystallization process, even when the heat and the braze or solder are not directed precisely to the places to be joined. Practice considerations for brazing and soldering. 18. special welding and joining topics. 19. joint evaluation and quality control. Brazing is a metal joining process in which two or more metal parts are joined by melting and flowing a filler metal into the joint, without melting the base metals. In the spectrum of joining processes, brazing and soldering lie between fusion welding and solid state welding. a filler metal is added in brazing and soldering as in most fusion welding operations; however, no melting of the base metals occurs, which is similar to solid state welding. This chapter presents the basic concept of brazing and soldering processes and fabrications conditions where these joining processes are found suitable. further, brazing filler, flux and temperature have also been described.

Soldering Brazing Welding Defects Pptx Practice considerations for brazing and soldering. 18. special welding and joining topics. 19. joint evaluation and quality control. Brazing is a metal joining process in which two or more metal parts are joined by melting and flowing a filler metal into the joint, without melting the base metals. In the spectrum of joining processes, brazing and soldering lie between fusion welding and solid state welding. a filler metal is added in brazing and soldering as in most fusion welding operations; however, no melting of the base metals occurs, which is similar to solid state welding. This chapter presents the basic concept of brazing and soldering processes and fabrications conditions where these joining processes are found suitable. further, brazing filler, flux and temperature have also been described.

Welding Brazing Soldering Pdf In the spectrum of joining processes, brazing and soldering lie between fusion welding and solid state welding. a filler metal is added in brazing and soldering as in most fusion welding operations; however, no melting of the base metals occurs, which is similar to solid state welding. This chapter presents the basic concept of brazing and soldering processes and fabrications conditions where these joining processes are found suitable. further, brazing filler, flux and temperature have also been described.

Comments are closed.