Difference Between Soldering And Brazing Explained

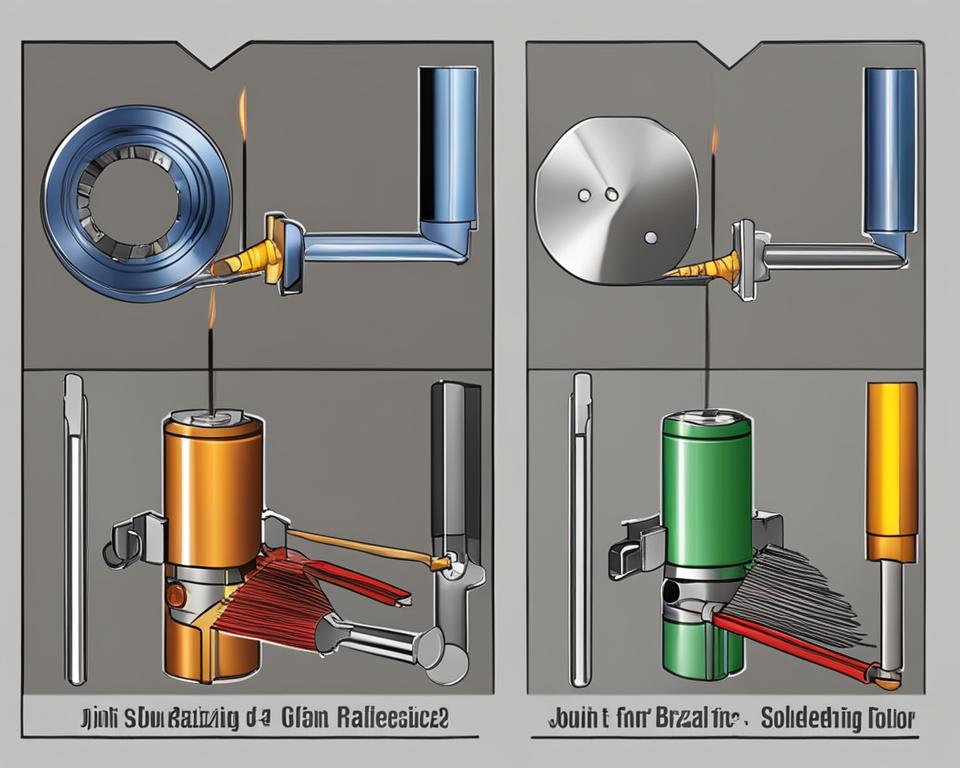

Difference Between Soldering And Brazing Difference Between – both soldering and brazing are metal joining processes used to join two similar or dissimilar metals but in different joining conditions. brazing is a welding technique used to join two pieces of metal together using a metallic filler that has been melted and flowed into the joint. This article aims to provide a comprehensive exploration of the differences between brazing and soldering, delving into their underlying mechanisms, material considerations, applications, advantages, and disadvantages.

Difference Between Soldering And Brazing Mech4study Soldering and brazing are two highly versatile and productive metal joining processes that utilize a filler alloy. in actuality, they differ significantly in their applications, required temperatures, and the strength of the final solder joint. Explore the distinctions between soldering and brazing, two metal joining techniques, including differences in filler materials, temperature, strength, and common applications. Both methods create strong bonds but work differently. brazing utilizes higher temperatures and filler metals, whereas soldering relies on lower temperatures to work with delicate electronic components. choosing the wrong technique can weaken joints or damage materials. The main difference between brazing and soldering is the filler metal’s melting temperature. processes above 840 °f constitute brazing, while soldering occurs below that threshold.

Difference Between Soldering And Brazing Explained Both methods create strong bonds but work differently. brazing utilizes higher temperatures and filler metals, whereas soldering relies on lower temperatures to work with delicate electronic components. choosing the wrong technique can weaken joints or damage materials. The main difference between brazing and soldering is the filler metal’s melting temperature. processes above 840 °f constitute brazing, while soldering occurs below that threshold. However, soldering and brazing have differences in the application processes, skills needed, gear and the temperature required. keep reading to learn more about the similarities, differences, and also advantages of the two methods. Understanding the key differences between soldering and brazing is crucial, as each process offers unique advantages depending on temperature ranges, material compatibility, and application requirements. Soldering is generally used for delicate tasks such as electronics and jewelry making, where precision is crucial and the heat input needs to be minimal. whereas brazing is favored for its strength in mechanical and plumbing applications, where the joints need to endure significant mechanical loads and high temperatures. The terms “hard soldering” and “soft soldering” are often used interchangeably with brazing and soldering, respectively. “soft soldering” refers to soldering with a low melting point alloy, while “hard soldering” usually refers to brazing, indicating a higher melting point alloy and stronger joint.

Difference Between Soldering And Brazing However, soldering and brazing have differences in the application processes, skills needed, gear and the temperature required. keep reading to learn more about the similarities, differences, and also advantages of the two methods. Understanding the key differences between soldering and brazing is crucial, as each process offers unique advantages depending on temperature ranges, material compatibility, and application requirements. Soldering is generally used for delicate tasks such as electronics and jewelry making, where precision is crucial and the heat input needs to be minimal. whereas brazing is favored for its strength in mechanical and plumbing applications, where the joints need to endure significant mechanical loads and high temperatures. The terms “hard soldering” and “soft soldering” are often used interchangeably with brazing and soldering, respectively. “soft soldering” refers to soldering with a low melting point alloy, while “hard soldering” usually refers to brazing, indicating a higher melting point alloy and stronger joint.

Comments are closed.