%22%22sizes%22%7b%2286%22%22the Kaizen Approach Continuous Improvement For Productivity 86×64

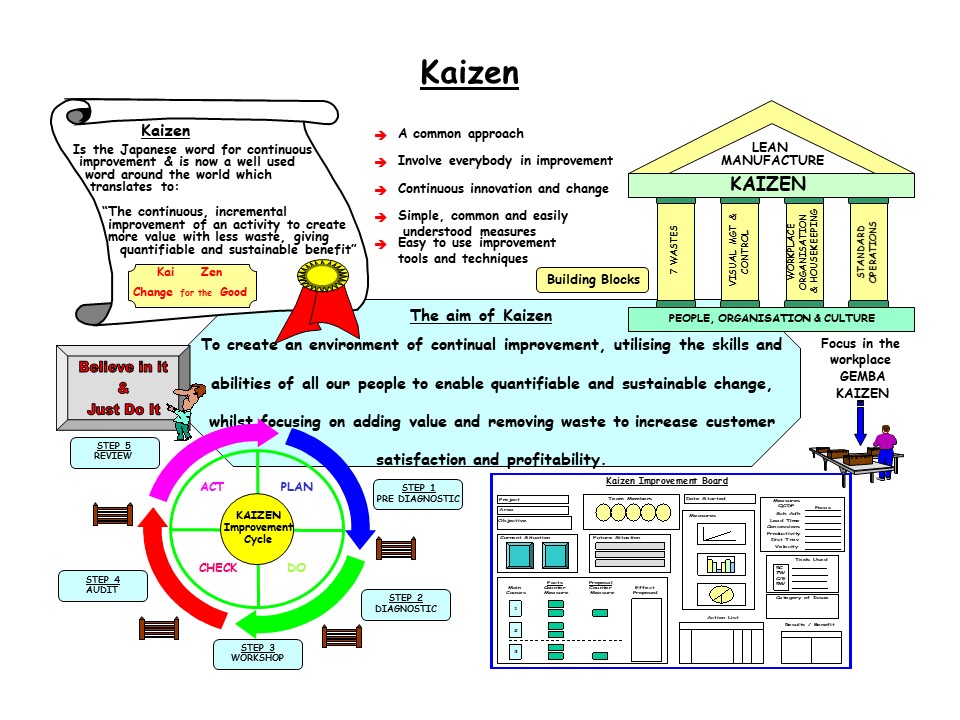

Kaizen Continuous Improvement Model Kaizen Process Im Vrogue Co Here’s our super informational clothing size chart that converts all sizing scales – x small, small, medium, large, x large, xx large and xxx large, us sizing and eu sizing. before online shopping, you had no choice but to go to clothing stores where you could try everything on before buying. The purpose of kaizen goes beyond simple productivity improvement. when done correctly, the process humanizes the workplace, eliminates overly hard work, and teaches people how to spot and eliminate waste in business processes.

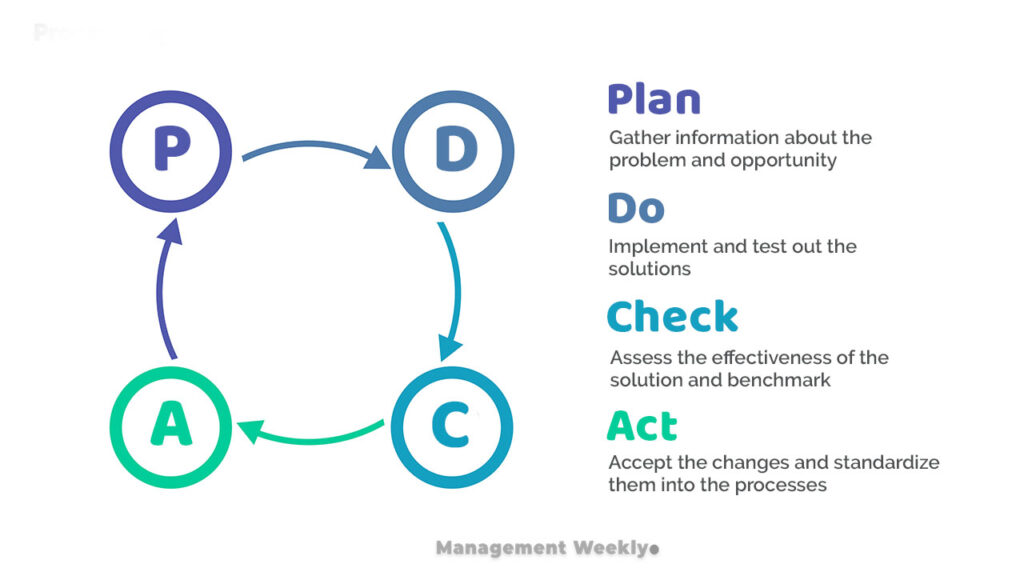

Understanding And Implementing The Kaizen Approach For Continuous This management course shows you how to use ‘lean’ methods to encourage continuous improvement in your team. more and more organizations are adopting the japanese kaizen approach to increase ‘lean’ efficiency and productivity in the workplace. Learn how this simple yet powerful philosophy of continuous improvement helps businesses and individuals achieve lasting success through small, consistent changes. The kaizen™ model for improving production to achieve flexibility and efficiency applies the principles of kaizen™ to enhance an organization’s production processes, giving it a greater ability to adapt quickly to changing customer needs, reduce waste, and maximize productivity. The primary goal of kaizen is to achieve continuous improvement across all aspects of a company’s operations through small, incremental changes. this involves identifying inefficiencies, developing solutions, testing them, and refining based on feedback.

Kaizen Model Of Continuous Improvement Management Weekly The kaizen™ model for improving production to achieve flexibility and efficiency applies the principles of kaizen™ to enhance an organization’s production processes, giving it a greater ability to adapt quickly to changing customer needs, reduce waste, and maximize productivity. The primary goal of kaizen is to achieve continuous improvement across all aspects of a company’s operations through small, incremental changes. this involves identifying inefficiencies, developing solutions, testing them, and refining based on feedback. In this article, we will explore strategies for implementing kaizen effectively, enabling organizations to foster a culture of continuous improvement. successful implementation of kaizen begins with cultivating a mindset that embraces change and continuous improvement. What is the kaizen approach? here you will find everything you need to know about the kaizen approach including the 6 key steps, the 5 elements of kaizen and how it is used in toyota!. Kaizen, which means “change for better” or “continuous improvement” in japanese, is a philosophy and practice that encourages small, incremental changes aimed at improving efficiency, productivity, and overall well being. Kaizen is a japanese philosophy of continuous improvement and excellence. popularized by masaaki imai, this approach is based on progressive, iterative actions designed to optimize processes, improve product quality and increase customer satisfaction.

Comments are closed.